Mastering the 40 Series Clutch: A Besiktas Perspective

The 40 Series Clutch has become a ubiquitous component in machinery, from industrial equipment to automotive applications. But what exactly makes this clutch so effective, and how can understanding its mechanics elevate the performance of any machine, including those used by our beloved Black Eagles? This article will delve deep into the inner workings of the 40 series clutch, explore its benefits, and discuss its importance in achieving optimal performance.

Understanding the Mechanics of the 40 Series Clutch

The 40 series clutch is a type of friction clutch, relying on the contact and interaction of friction materials to transmit torque. This mechanical device engages and disengages the power transmission between a driving shaft and a driven shaft. The “40” designation typically refers to a specific size or series within a manufacturer’s product line, often indicating the clutch’s torque capacity and dimensions. Its reliability and versatility have made it a popular choice across numerous industries. Imagine the precision needed in the maintenance of our stadium equipment – the 40 series clutch plays a vital role.

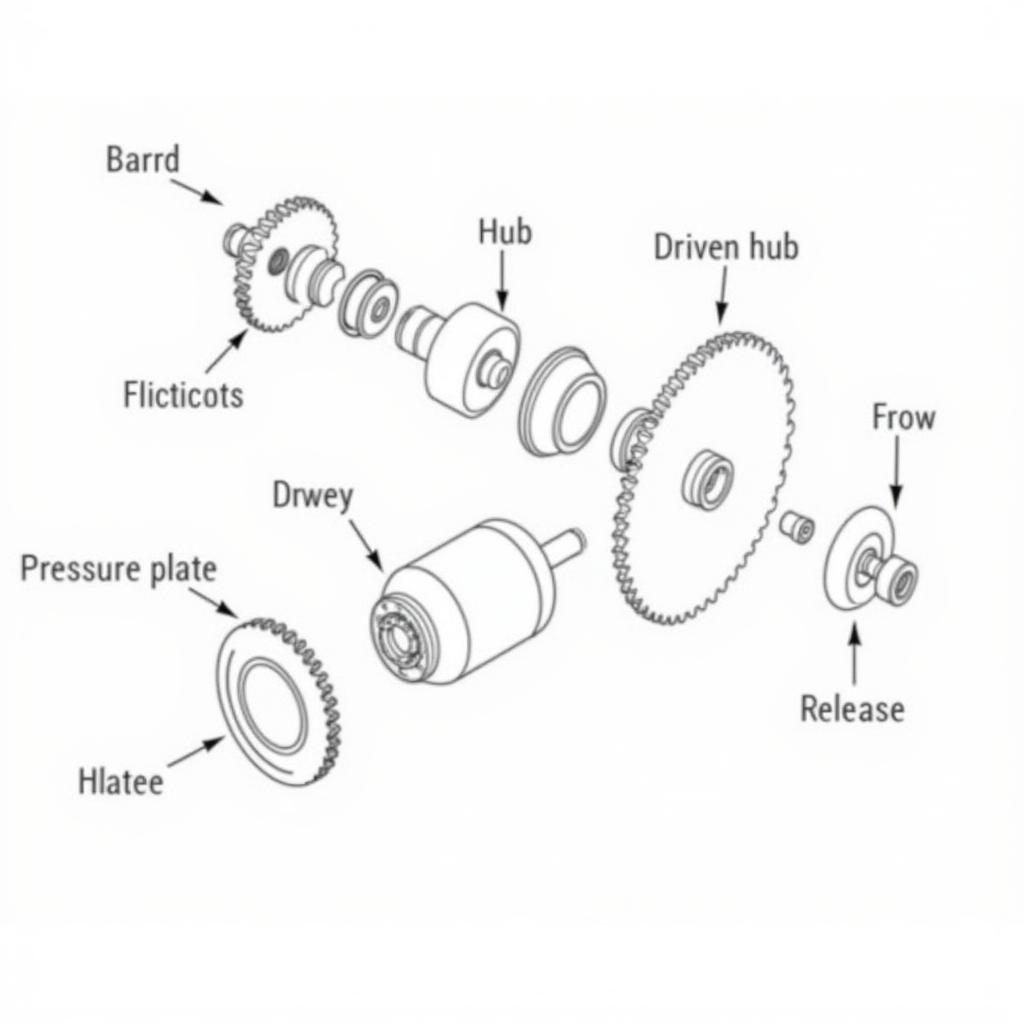

Key Components and Their Function

The 40 series clutch consists of several essential components working together seamlessly. These include the driving hub connected to the power source, the driven hub connected to the output shaft, and the friction disc nestled between the two hubs. Pressure plates apply force to the friction disc, creating the necessary friction for torque transmission. The release mechanism allows for disengagement, interrupting the power flow when required. Understanding these components is crucial for troubleshooting and maintenance, ensuring peak performance.

40 Series Clutch Components Diagram

40 Series Clutch Components Diagram

Benefits of Utilizing a 40 Series Clutch

The widespread adoption of the 40 series clutch isn’t accidental. Its inherent advantages make it a preferred choice in various applications. Its compact design allows for integration into tight spaces, a significant benefit in complex machinery. The high torque capacity ensures efficient power transmission, essential for demanding operations. And its robust construction guarantees durability and long service life, reducing downtime and maintenance costs. This reliability is crucial even in something seemingly simple like the operation of our training ground’s equipment – ensuring everything runs smoothly for our players.

Advantages in Different Applications

From agricultural machinery to industrial automation, the 40 series clutch shines. In agriculture, it allows for precise control of implements, enabling farmers to optimize their work. In industrial settings, it ensures smooth operation of conveyor belts and other critical systems. most grand slams mlb history Even in seemingly unrelated fields, the principles of efficient power transmission are key. The versatility of the 40 series clutch makes it an invaluable asset across various sectors.

40 Series Clutch Applications in Different Industries

40 Series Clutch Applications in Different Industries

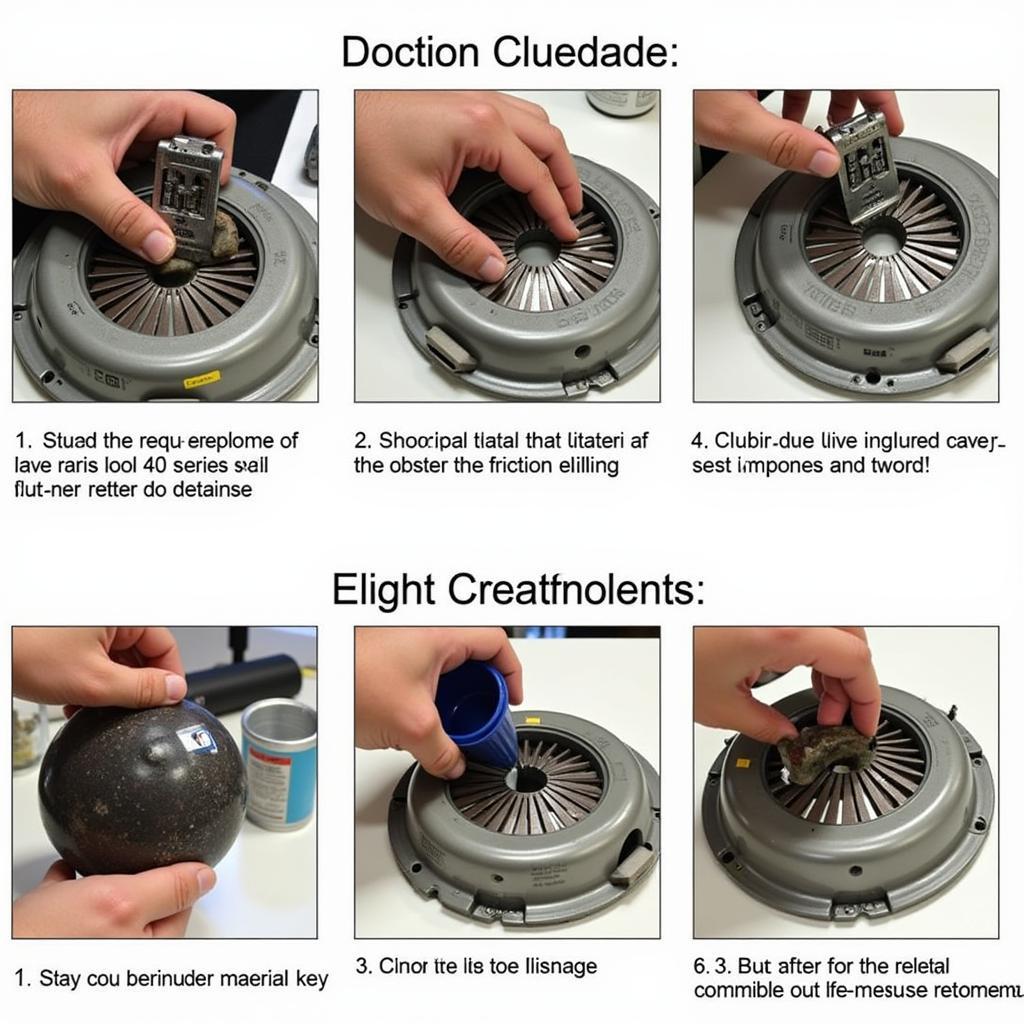

Maintaining and Troubleshooting the 40 Series Clutch

Proper maintenance is vital for extending the lifespan and ensuring optimal performance of any 40 series clutch. Regular inspections should be conducted to check for wear and tear on the friction material, pressure plate, and release mechanism. Lubrication is essential to reduce friction and prevent premature wear. Promptly addressing any issues, such as slipping or unusual noises, can prevent more significant problems down the line. Think of it like ensuring the smooth operation of our stadium lights – regular checks are key.

Common Issues and Solutions

Some common issues encountered with 40 series clutches include slippage, chatter, and failure to engage or disengage. Slipping can be caused by worn friction material or insufficient pressure plate force. Chatter can result from misalignment or uneven wear. Failure to engage or disengage may indicate a problem with the release mechanism. Understanding these common issues and their solutions allows for quick and effective troubleshooting, minimizing downtime.

Conclusion: The Power Behind the Performance

The 40 series clutch, with its robust design and versatile applications, is a vital component in countless machines. Understanding its mechanics, benefits, and maintenance requirements is crucial for optimizing performance and ensuring longevity. Just as Besiktas strives for excellence on the field, we must ensure our equipment and infrastructure are operating at their best, and the 40 series clutch plays a crucial role in that endeavor. From the training ground to the stadium, the power of the 40 series clutch is undeniable.

40 Series Clutch Maintenance Best Practices

40 Series Clutch Maintenance Best Practices

FAQ

- What is the lifespan of a 40 series clutch?

- How can I identify a worn-out 40 series clutch?

- What are the common causes of clutch slippage?

- How often should I lubricate my 40 series clutch?

- What are the different types of 40 series clutches available?

- What are the key considerations when selecting a 40 series clutch?

- Where can I find replacement parts for my 40 series clutch?

For any assistance, please contact us at Phone Number: 0989060241, Email: [email protected] or visit our address: Tở 2, ấp 5, An Khương, Hớn Quản, Bình Phước, Việt Nam. We have a 24/7 customer service team.