Understanding No. 2 Brass Wood Screws

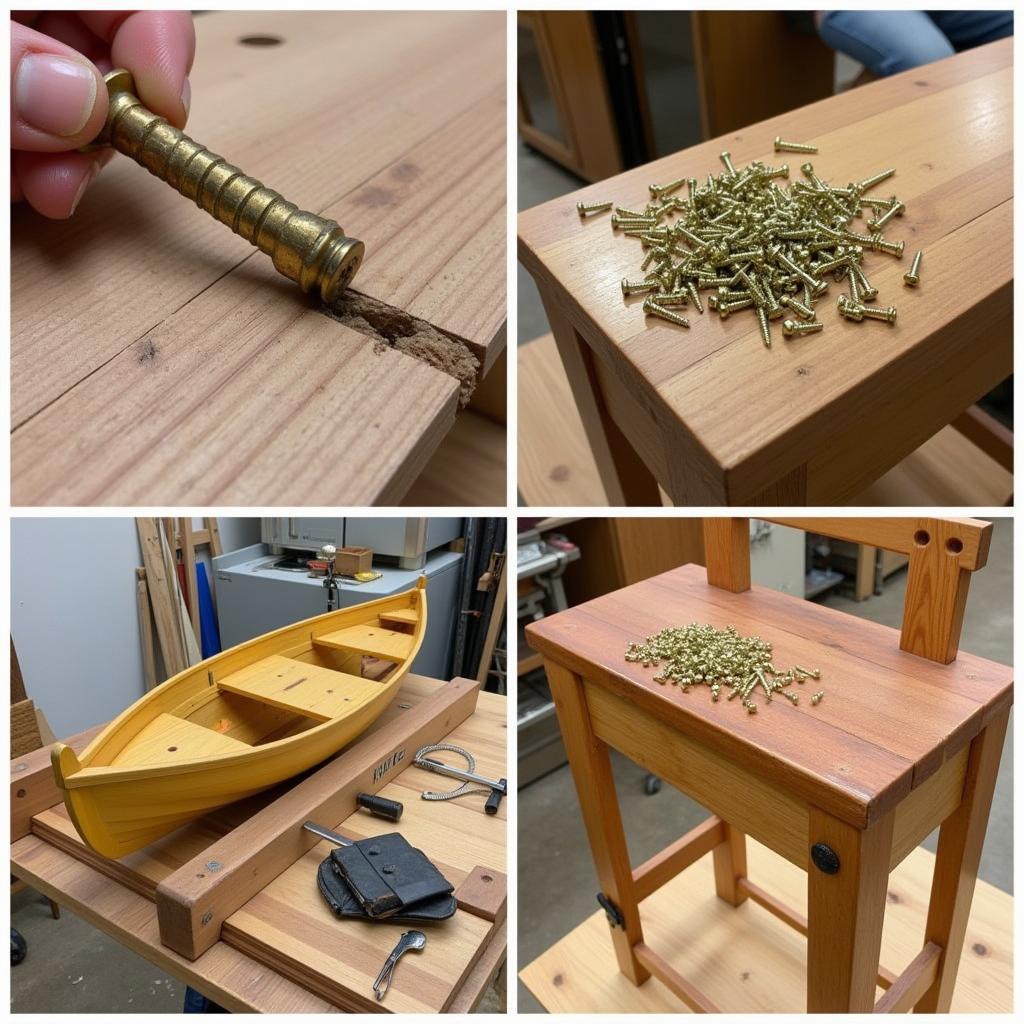

No. 2 Brass Wood Screws are a common choice for a variety of woodworking projects, offering a blend of strength, corrosion resistance, and aesthetic appeal. Choosing the right screw can be the difference between a sturdy, long-lasting piece and one that falls apart. This comprehensive guide will delve into everything you need to know about no. 2 brass wood screws, from their various uses and sizes to their advantages and disadvantages.

Choosing the Right No. 2 Brass Wood Screw

Selecting the appropriate no. 2 brass wood screw requires considering several factors, including the type of wood, the thickness of the material being joined, and the desired finish. The length of the screw is crucial for ensuring a secure hold without splitting the wood. Too short, and the joint will be weak; too long, and the screw may protrude or damage the surrounding material.

The head style is another essential consideration. Common head styles include flat, oval, and pan head. Each serves a different purpose, from countersinking flush with the surface to providing a decorative finish.

For exterior applications or projects exposed to moisture, the corrosion resistance of brass makes these screws a particularly good choice. They maintain their strength and appearance over time, even in harsh environments.

Variety of No. 2 Brass Wood Screws

Variety of No. 2 Brass Wood Screws

Benefits of Using No. 2 Brass Wood Screws

No. 2 brass wood screws offer several advantages, making them a preferred choice for many woodworkers and DIY enthusiasts. Their corrosion resistance is a standout feature, ensuring longevity and preventing unsightly rust stains. This is particularly beneficial for outdoor projects or applications where moisture is a concern.

Beyond their practical benefits, no. 2 brass wood screws also provide an aesthetically pleasing finish. The warm, golden hue of brass adds a touch of elegance to projects, making them suitable for furniture, cabinetry, and decorative woodworking.

They are also relatively easy to work with, readily driving into most types of wood without requiring pre-drilling in many cases. This makes them an efficient choice for both small and large-scale projects.

Different Applications of No. 2 Brass Wood Screws

From securing hinges and hardware to assembling delicate wooden boxes and crafting intricate models, the applications of no. 2 brass wood screws are diverse. Their small size makes them ideal for fine woodworking, where precision and a clean finish are paramount. They’re also commonly used in boat building and marine applications due to their resistance to saltwater corrosion.

Applications of No. 2 Brass Wood Screws

Applications of No. 2 Brass Wood Screws

Common Questions About No. 2 Brass Wood Screws

What are the standard sizes available for no. 2 brass wood screws? No. 2 brass wood screws typically range in length from ¼ inch to 1 inch, with variations in between.

Do I need to pre-drill holes for no. 2 brass wood screws? Pre-drilling is often recommended, especially in hardwoods, to prevent splitting. A pilot hole slightly smaller than the screw’s shank diameter is usually sufficient.

Can I use no. 2 brass wood screws with treated lumber? While brass is corrosion-resistant, it’s important to choose screws specifically designed for treated lumber to ensure long-term performance.

“When working with delicate materials, the precise size and corrosion resistance of no. 2 brass wood screws are invaluable,” says renowned woodworker, Amelia Carter. “They provide the strength and durability needed without compromising the aesthetic integrity of the piece.”

Comparing Brass Screws with Other Materials

While brass offers excellent corrosion resistance and aesthetic appeal, other materials like steel and stainless steel are also common choices. Steel screws are generally stronger but susceptible to rust, while stainless steel provides a good balance of strength and corrosion resistance, albeit at a higher cost. Choosing the right material depends on the specific application and environmental factors.

“Understanding the properties of different screw materials is essential for achieving optimal results,” advises experienced craftsman, David Miller. “Consider the environment and the specific demands of your project when making your selection.”

Comparing Brass and Steel Wood Screws

Comparing Brass and Steel Wood Screws

Conclusion

No. 2 brass wood screws are a versatile and valuable asset in any woodworker’s toolkit. Their corrosion resistance, ease of use, and aesthetic appeal make them a suitable choice for a wide range of projects. By understanding their characteristics and applications, you can choose the right screw for the job, ensuring a strong, durable, and beautiful finished product. Remember to consider factors like length, head style, and the type of wood being used to achieve the best results.

When you need assistance, please contact Phone Number: 0989060241, Email: [email protected] Or visit us at: Lot 2, Hamlet 5, An Khuong, Hon Quan, Binh Phuoc, Vietnam. We have a 24/7 customer service team.