Understanding the 1 1/8 Elbow

The 1 1/8 Elbow, a seemingly niche term, plays a significant role in various applications, particularly in plumbing and piping systems. This article delves into the specifics of the 1 1/8 elbow, exploring its uses, materials, and importance in different contexts.

Decoding the 1 1/8 Elbow: Size and Significance

The “1 1/8” in “1 1/8 elbow” refers to the nominal pipe size (NPS) the elbow connects to. This measurement signifies the inner diameter of the pipe, influencing the flow rate and pressure within the system. Choosing the correct elbow size is crucial for optimal system performance and preventing leaks or blockages. The 1 1/8 elbow, slightly larger than the more common 1-inch elbow, caters to specific applications where a larger flow capacity is required.

Material Matters: Choosing the Right 1 1/8 Elbow

The material of a 1 1/8 elbow is just as important as its size. Common materials include:

- PVC: Cost-effective and suitable for drain and waste lines.

- Copper: Durable and resistant to corrosion, ideal for water supply lines.

- Stainless Steel: Highly resistant to corrosion and high temperatures, used in demanding applications.

Selecting the appropriate material ensures the 1 1/8 elbow can withstand the specific conditions of the system, such as pressure, temperature, and the nature of the fluid being transported.

Applications of the 1 1/8 Elbow

The versatility of the 1 1/8 elbow makes it suitable for diverse applications across various industries:

- Plumbing: Connecting pipes in residential and commercial plumbing systems.

- HVAC: Directing airflow in heating and cooling systems.

- Industrial Piping: Transporting fluids and gases in industrial settings.

- Irrigation: Changing the direction of water flow in irrigation systems.

What are the different angles available for 1 1/8 elbows?

Common angles for 1 1/8 elbows are 45 degrees and 90 degrees, allowing for various directional changes in piping.

Can I use a 1 1/8 elbow with a 1-inch pipe?

No, using mismatched sizes can lead to leaks and reduced system efficiency.

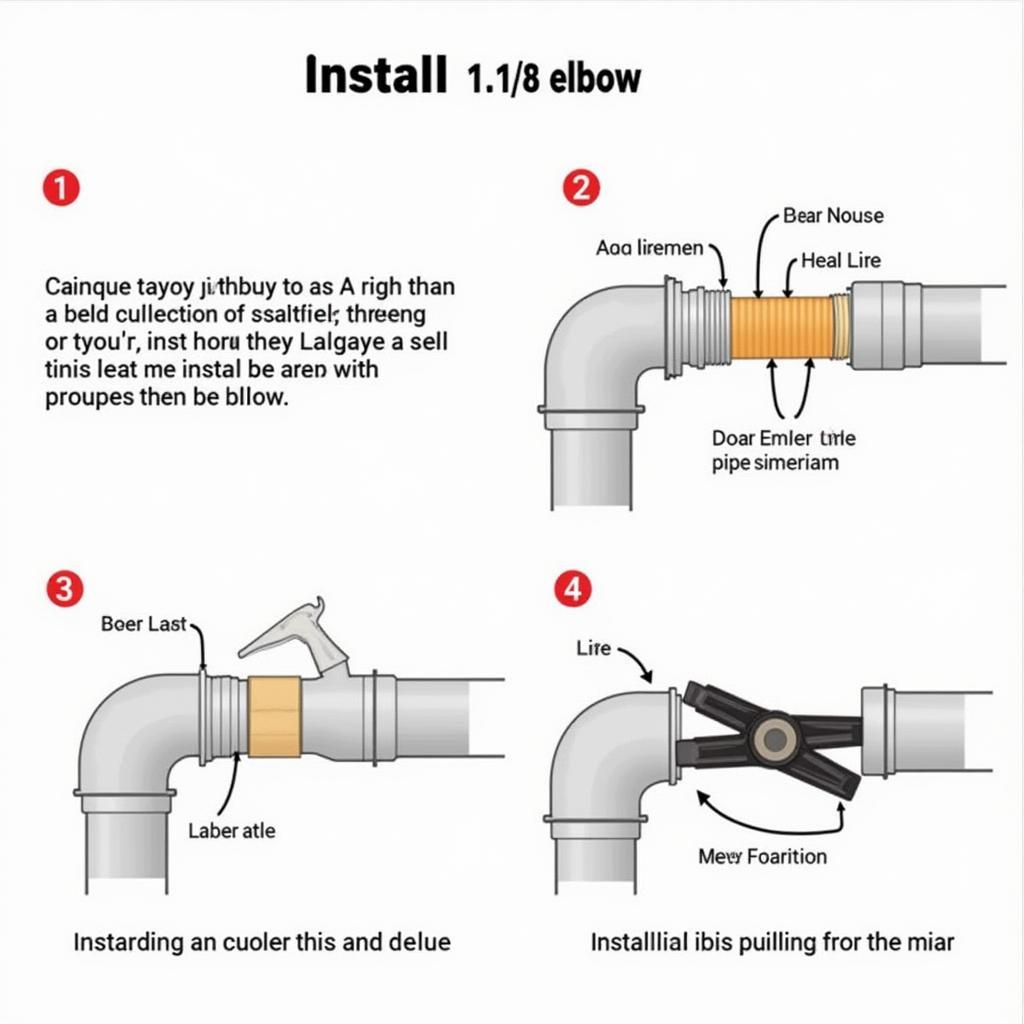

The Importance of Proper Installation

Correct installation is crucial for the effectiveness of a 1 1/8 elbow. Improper installation can lead to leaks, reduced flow, and even system failure. Ensuring proper sealing and secure connections is essential for optimal performance.

How do I ensure a leak-free connection with a 1 1/8 elbow?

Use appropriate sealant and follow manufacturer instructions for tightening connections.

What tools do I need to install a 1 1/8 elbow?

Common tools include pipe wrenches, pipe cutters, and measuring tapes.

Proper Installation of a 1 1/8 Elbow

Proper Installation of a 1 1/8 Elbow

1 1/8 Elbow: Ensuring Efficient Flow

Choosing the right 1 1/8 elbow – considering size, material, and proper installation – ensures efficient flow and system integrity. These seemingly small components play a crucial role in the overall performance and longevity of various piping systems. Understanding the nuances of the 1 1/8 elbow empowers users to make informed decisions for their specific needs.

FAQ

- What does 1 1/8 in 1 1/8 elbow represent? It signifies the nominal pipe size the elbow connects to.

- What are common materials for 1 1/8 elbows? PVC, copper, and stainless steel.

- What are the common angles for 1 1/8 elbows? 45 and 90 degrees.

- Why is proper installation important? To prevent leaks and ensure system efficiency.

- Where can 1 1/8 elbows be used? In plumbing, HVAC, industrial piping, and irrigation.

- Can I use a 1 1/8 elbow with a different size pipe? No, using mismatched sizes can cause problems.

- How do I choose the right 1 1/8 elbow for my project? Consider the application, pressure, temperature, and the fluid being transported.

Need support? Contact us at Phone Number: 0989060241, Email: [email protected] Or visit us at: Tở 2, ấp 5, An Khương, Hớn Quản, Bình Phước, Việt Nam. We have a 24/7 customer service team.