Snap Tie Concrete Wall: A Comprehensive Guide

Snap Tie Concrete Walls are a common and efficient construction method used for creating robust and durable concrete structures. This guide delves into the intricacies of snap tie concrete walls, covering everything from their fundamental principles to advanced applications.

Understanding Snap Tie Concrete Wall Systems

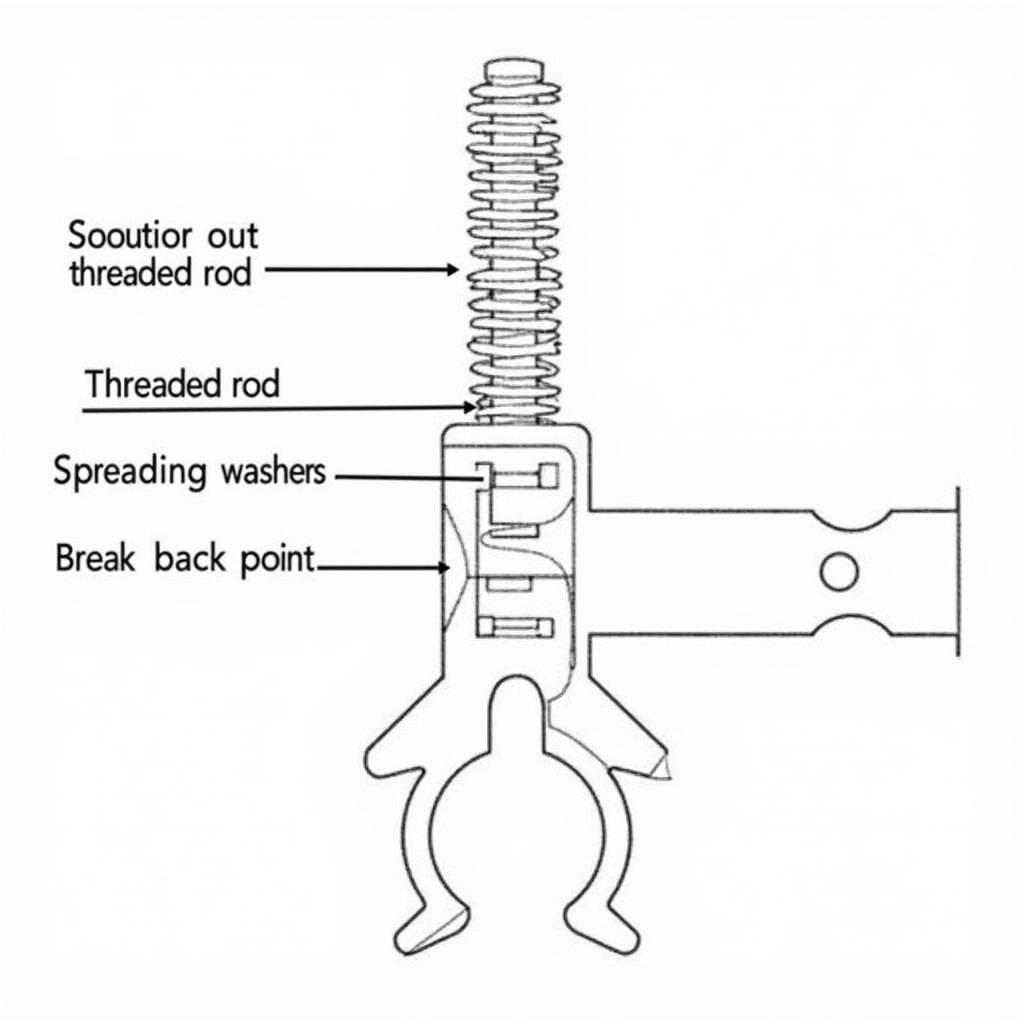

Snap ties are essential components in concrete wall construction. They consist of a threaded rod with a spreading washer at each end and are used to hold the formwork together against the pressure of fresh concrete.  Snap Tie Components Diagram These ties play a critical role in ensuring the structural integrity and dimensional accuracy of the poured concrete wall. The “snap” refers to the designed break-back point of the tie, leaving a portion embedded in the concrete after the forms are removed.

Snap Tie Components Diagram These ties play a critical role in ensuring the structural integrity and dimensional accuracy of the poured concrete wall. The “snap” refers to the designed break-back point of the tie, leaving a portion embedded in the concrete after the forms are removed.

Advantages of Using Snap Ties

Snap tie systems offer several advantages over other methods:

- Speed and Efficiency: Snap ties are relatively quick to install and remove, speeding up the construction process.

- Cost-Effectiveness: The ease of use and reusability of certain components contributes to lower overall project costs.

- Versatility: Snap ties are adaptable to various wall thicknesses and concrete pours.

- Strength and Stability: They provide the necessary support to withstand the hydrostatic pressure of wet concrete.

Types of Snap Ties and Their Applications

Several types of snap ties exist, each designed for specific applications:

- Standard Snap Ties: Commonly used for general concrete wall construction.

- Heavy-Duty Snap Ties: Employed in situations requiring greater load-bearing capacity.

- She-Bolt Ties: Offer a clean break and are often preferred for architectural concrete finishes.

- Multi-Tie Systems: Allow for ganging multiple ties together for large wall sections.

Choosing the Right Snap Tie for Your Project

Selecting the appropriate snap tie depends on factors such as:

- Wall thickness: Thicker walls require longer and stronger ties.

- Concrete pressure: Higher concrete pours exert greater pressure on the forms.

- Finish requirements: Architectural concrete often necessitates ties that minimize surface imperfections.

Snap Tie Installation Best Practices

Proper installation is crucial for achieving optimal performance and preventing issues:

- Spacing and Placement: Follow engineering specifications for proper tie spacing.

- Torque Specifications: Ensure correct tightening to achieve the desired clamping force.

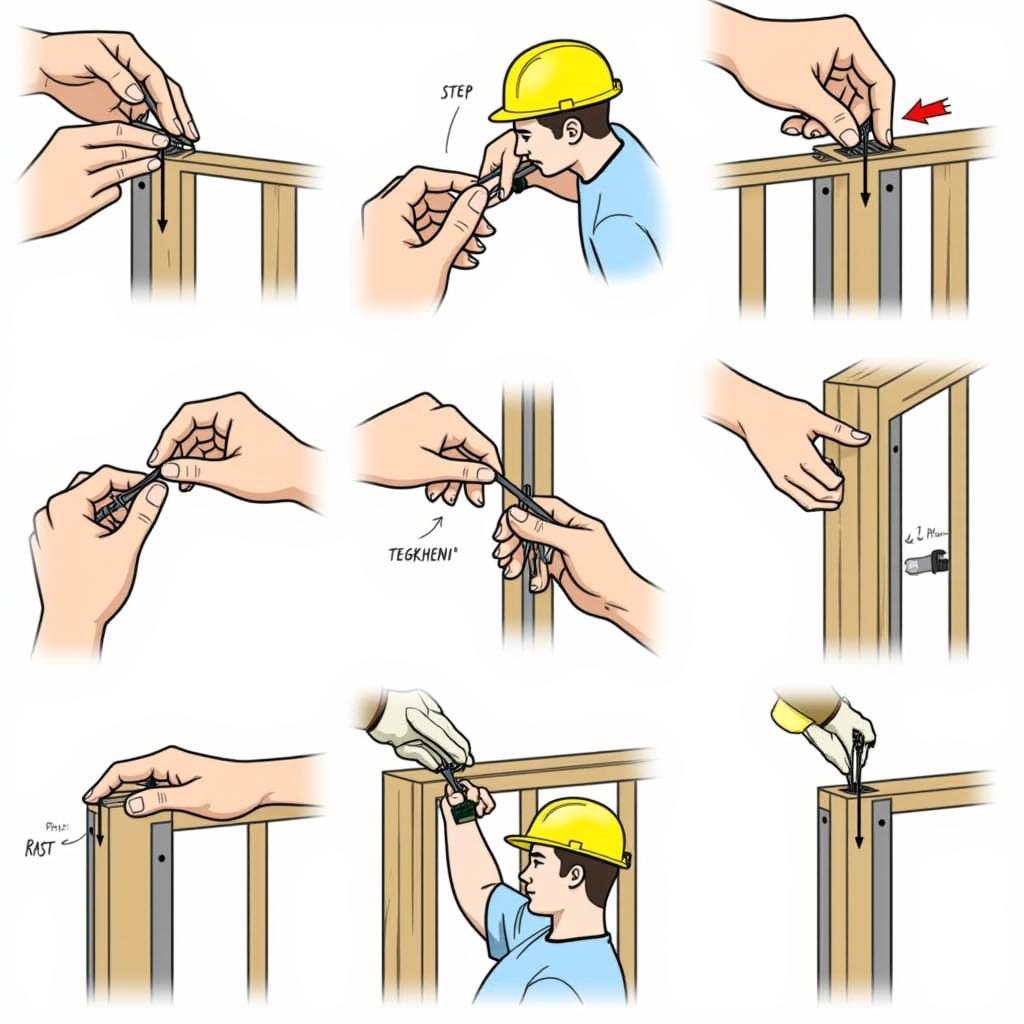

Snap Tie Installation Process

Snap Tie Installation Process - Formwork Preparation: Ensure the forms are clean, level, and properly braced.

Addressing Common Challenges with Snap Tie Concrete Walls

Some common challenges and their solutions include:

- Tie Breakage: Can be caused by improper installation, excessive pressure, or defective ties.

- Concrete Leakage: May occur due to inadequate sealing around the ties.

- Surface Imperfections: Proper tie selection and patching techniques can minimize these issues.

Conclusion

Snap tie concrete walls provide an efficient and reliable method for constructing durable concrete structures. By understanding the different types of snap ties, proper installation techniques, and potential challenges, you can ensure successful project outcomes. Utilizing snap ties effectively is key to achieving strong, stable, and aesthetically pleasing concrete walls.

FAQ

- What is the purpose of a snap tie?

- How are snap ties installed?

- What are the different types of snap ties?

- How do I choose the right snap tie for my project?

- What are the common problems associated with snap tie concrete walls?

- How can I prevent concrete leakage around snap ties?

- What are the best practices for snap tie installation?

If you need assistance, please contact us at Phone Number: 0989060241, Email: [email protected], or visit our address: Tở 2, ấp 5, An Khương, Hớn Quản, Bình Phước, Việt Nam. We have a 24/7 customer support team.