Understanding Transparent Plastic Rods: Properties, Applications, and Benefits

Transparent Plastic Rods are versatile materials that find applications across various industries. They offer a unique combination of optical clarity, lightweight, and durability, making them suitable for a wide range of products and solutions.

Types of Transparent Plastic Rods

Types of Transparent Plastic Rods

What are Transparent Plastic Rods?

Transparent plastic rods are solid, cylindrical structures made from various types of transparent or translucent plastics. These rods can be extruded or molded into specific diameters, lengths, and shapes to meet diverse application requirements. The transparency of these rods allows light to pass through them, making them suitable for applications where visibility or light transmission is crucial.

Common Materials for Transparent Plastic Rods

Several types of plastics are used in the production of transparent plastic rods, each offering a unique set of properties:

- Acrylic (PMMA): Known for its excellent optical clarity, impact resistance, and UV resistance. Ideal for applications requiring high light transmission, such as lenses, light guides, and displays.

- Polycarbonate (PC): Offers exceptional impact resistance, making it suitable for demanding applications like safety glasses, machine guards, and protective shields.

- Polystyrene (PS): A cost-effective option with good transparency and stiffness. Often used in disposable laboratory equipment, packaging, and consumer products.

- Nylon: Provides a balance of strength, flexibility, and chemical resistance. Suitable for applications requiring durability and resistance to wear and tear.

Applications of Transparent Plastic Rods

Applications of Transparent Plastic Rods

Key Properties of Transparent Plastic Rods

- Optical Clarity: Allows light to pass through with minimal distortion, making them suitable for lenses, light guides, and other optical applications.

- Lightweight: Reduces overall weight and facilitates ease of handling and installation.

- Durability: Offers resistance to impact, chemicals, and UV radiation, ensuring longevity and performance in various environments.

- Versatility: Can be easily cut, shaped, and machined into various forms, enabling customization for specific applications.

Applications of Transparent Plastic Rods

The unique properties of transparent plastic rods make them suitable for a wide range of applications across various industries:

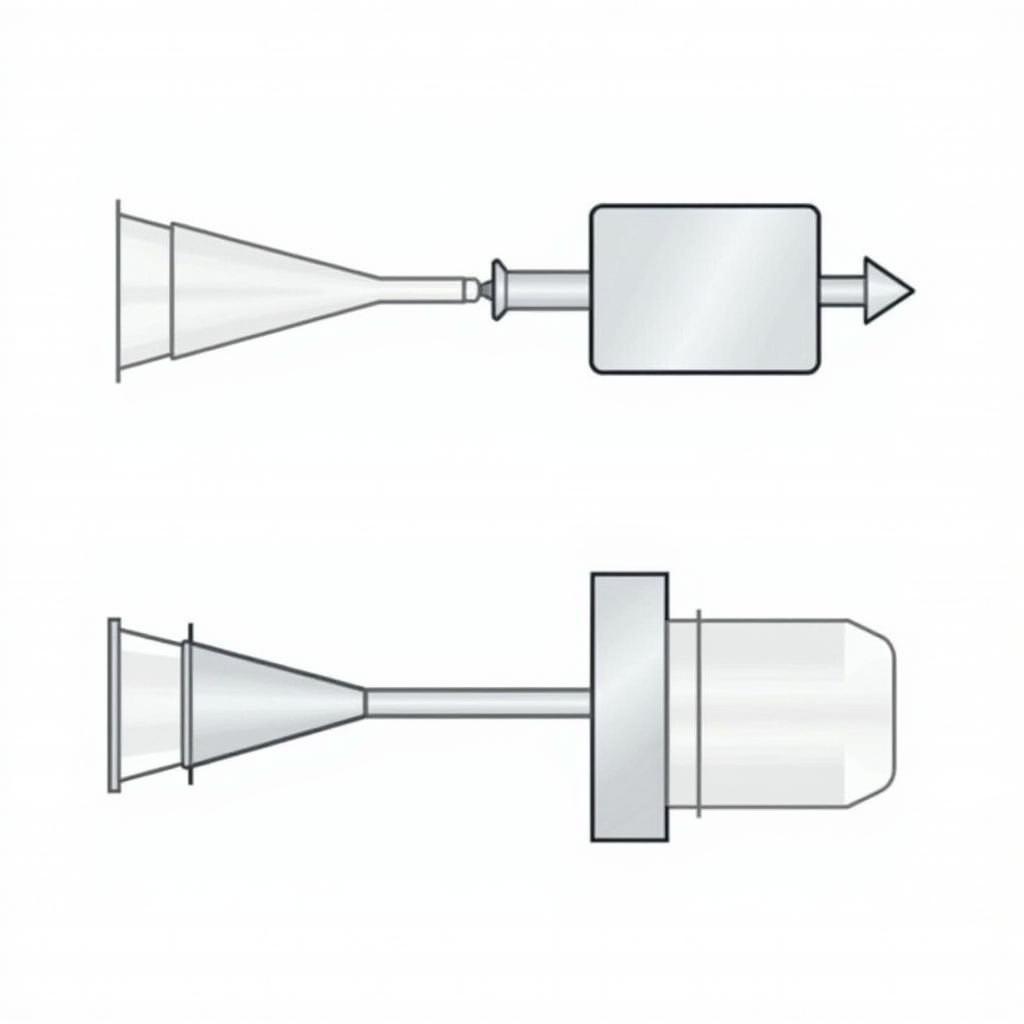

- Optics and Photonics: Lenses, light guides, optical fibers, prisms, and other optical components.

- Medical Devices: Surgical instruments, catheters, endoscopes, and other medical devices requiring biocompatibility and sterilization capabilities.

- Architecture and Construction: Decorative elements, railings, handrails, light fixtures, and architectural models.

- Consumer Goods: Display cases, furniture, household items, toys, and decorative items.

- Industrial Applications: Machine components, safety guards, fluid level indicators, and other industrial equipment requiring visibility or light transmission.

Benefits of Using Transparent Plastic Rods

- Cost-effectiveness: Compared to traditional materials like glass, transparent plastic rods offer a cost-effective alternative without compromising on performance.

- Design Flexibility: The versatility of these rods allows for complex shapes and designs, providing greater design freedom for engineers and designers.

- Ease of Fabrication: Plastic rods can be easily cut, shaped, and machined using conventional tools, simplifying the manufacturing process.

- Safety: The lightweight and impact-resistant nature of many transparent plastics makes them a safer alternative to glass in certain applications.

Manufacturing Process of Transparent Plastic Rods

Manufacturing Process of Transparent Plastic Rods

Choosing the Right Transparent Plastic Rod

Selecting the appropriate transparent plastic rod for a specific application depends on several factors:

- Material Properties: Consider the required optical clarity, impact resistance, chemical resistance, and UV resistance.

- Dimensions: Determine the required diameter, length, and tolerances based on the application’s needs.

- Surface Finish: Choose between smooth, polished, or textured surfaces depending on the desired aesthetic and functional requirements.

“When choosing a transparent plastic rod, it’s crucial to consider the specific application requirements, such as the operating environment, load-bearing capacity, and desired optical properties,” says Dr. Emily Carter, a materials scientist specializing in polymer technology. “Consulting with a material specialist can help ensure the selection of the most suitable material for optimal performance.”

Conclusion

Transparent plastic rods are versatile materials offering a unique combination of optical clarity, durability, and design flexibility. Their wide range of applications across various industries highlights their significance in modern manufacturing and product development. By understanding the properties, applications, and benefits of transparent plastic rods, engineers and designers can leverage these materials to create innovative and efficient solutions across various sectors.

FAQ

1. What is the difference between transparent and translucent plastic rods?

Transparent plastic rods allow light to pass through with minimal distortion, providing a clear view of objects behind them. Translucent rods, on the other hand, allow light to pass through but scatter it, resulting in a diffused or blurred view.

2. Can transparent plastic rods be used outdoors?

Yes, many transparent plastic rods offer UV resistance, making them suitable for outdoor applications. However, it’s crucial to select materials specifically designed for outdoor use to ensure long-term performance.

3. What are the typical sizes available for transparent plastic rods?

Transparent plastic rods are available in a wide range of diameters and lengths. Common diameters range from a few millimeters to several inches, while lengths can vary from a few centimeters to several meters.

4. How are transparent plastic rods cut and shaped?

Plastic rods can be cut using saws, shears, or laser cutting techniques. Shaping can be achieved through bending, molding, or machining processes depending on the complexity of the desired shape.

5. Where can I purchase transparent plastic rods?

Transparent plastic rods are available from various suppliers specializing in plastic materials and fabrication. Online retailers and distributors also offer a wide selection of rods to meet diverse application requirements.

6. Can transparent plastic rods be recycled?

Yes, many types of plastic rods are recyclable. However, recycling processes and regulations vary depending on the specific type of plastic used.

7. Are there any safety concerns when using transparent plastic rods?

While generally safe, it’s important to handle plastic rods with care to avoid sharp edges during cutting or machining. Additionally, selecting materials with appropriate fire ratings is crucial for applications where fire safety is a concern.

Need further assistance? Contact our team at 0989060241, [email protected], or visit us at Tở 2, ấp 5, An Khương, Hớn Quản, Bình Phước, Việt Nam. Our dedicated customer support team is available 24/7 to address your inquiries.

Explore our website for more information on various materials and solutions.