Understanding PVC Strapping Requirements

PVC strapping is a common packaging solution known for its strength, flexibility, and cost-effectiveness. This article delves into the key Pvc Strapping Requirements for various applications, ensuring secure and efficient packaging for your goods.

Key Considerations for PVC Strapping Requirements

Choosing the right PVC strapping involves understanding several key factors, including the type of goods being packaged, the weight and dimensions of the package, and the environmental conditions it will be exposed to. These factors determine the necessary tensile strength, elongation, and width of the strapping. Don’t underestimate the importance of proper tensioning and sealing tools, which are crucial for achieving a secure and reliable package.

Tensile Strength and Elongation: Critical PVC Strapping Requirements

Tensile strength, measured in pounds or kilograms, indicates the maximum force the strapping can withstand before breaking. Higher tensile strength is essential for heavier or more fragile items. Elongation, expressed as a percentage, measures the strapping’s ability to stretch and recover. Sufficient elongation helps absorb shocks and vibrations during transit, protecting the packaged goods.

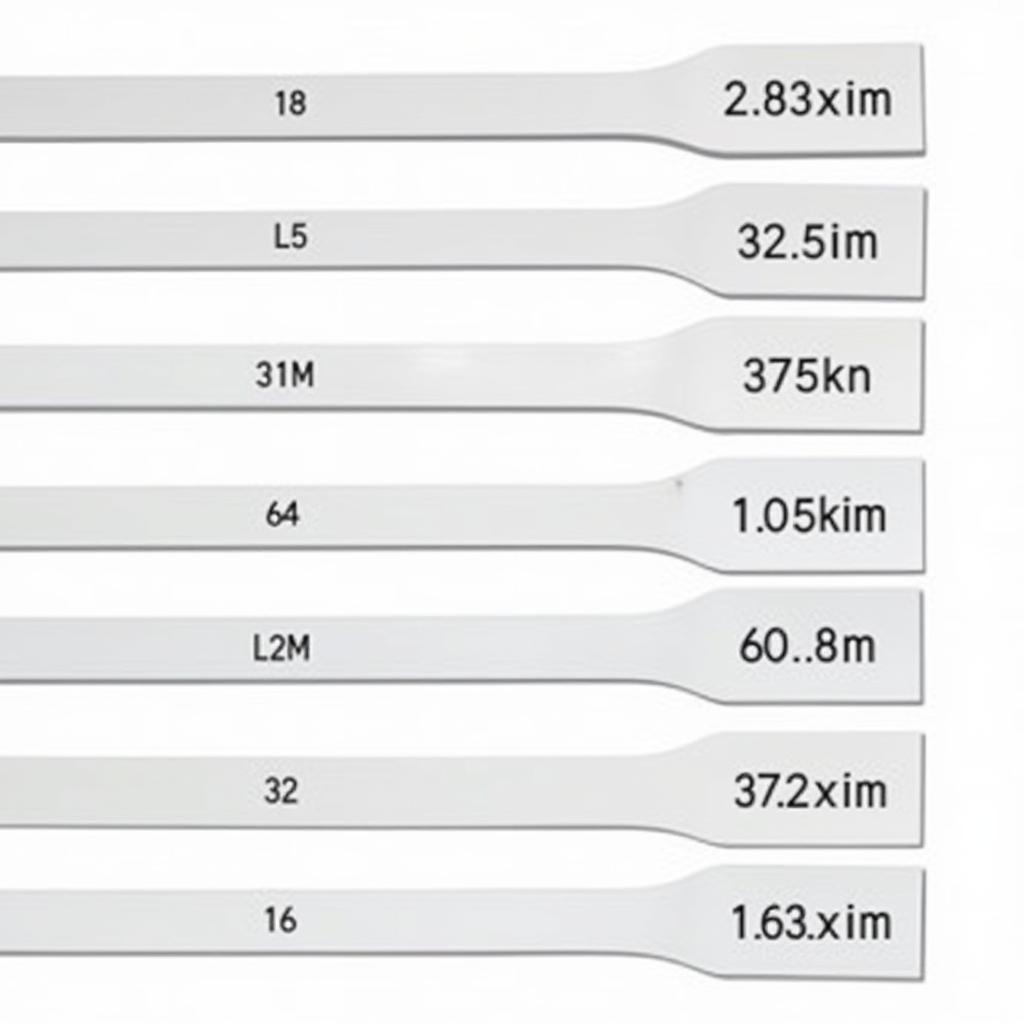

Width and Thickness: Finding the Right Balance

The width and thickness of the PVC strapping also contribute to its overall strength and suitability for different applications. Wider strapping provides better weight distribution and reduces the risk of cutting into the packaged goods. Thicker strapping offers higher tensile strength but may be less flexible and more difficult to apply.

Environmental Factors: Protecting Against the Elements

Considering the environmental conditions during storage and transportation is essential. Exposure to extreme temperatures, humidity, or UV radiation can affect the performance of PVC strapping. Choosing UV-resistant or weather-resistant strapping is crucial for outdoor applications or prolonged storage.

PVC Strapping Width and Thickness Comparison

PVC Strapping Width and Thickness Comparison

Common Applications and Their Specific PVC Strapping Requirements

Different industries have unique pvc strapping requirements. For example, the construction industry often requires heavy-duty strapping for securing building materials, while the food industry prioritizes hygiene and food-safe strapping options. Understanding these specific needs is crucial for selecting the appropriate strapping solution.

Securing Palletized Goods: A Common Use Case

Palletized goods require robust strapping to withstand the rigors of shipping and handling. High tensile strength and proper tensioning are essential for preventing load shifting and damage.

Bundling Products: Streamlining Packaging Processes

PVC strapping is also widely used for bundling smaller items together, such as newspapers, magazines, or lumber. This simplifies handling and reduces the risk of individual items getting lost or damaged.

Best Practices for Applying PVC Strapping

Proper application techniques are critical for maximizing the effectiveness of PVC strapping. Using the right tensioning and sealing tools ensures a secure and consistent seal, minimizing the risk of breakage during transit.

PVC Strapping Application Tools

PVC Strapping Application Tools

Expert Insight: John Smith, Senior Packaging Engineer at Acme Packaging Solutions, advises, “Choosing the right PVC strapping involves a careful evaluation of your specific needs and the conditions your packaged goods will encounter. Don’t hesitate to consult with a packaging expert to ensure you’re using the most appropriate solution.”

Expert Insight: Jane Doe, Logistics Manager at Global Shipping Inc., adds, “Proper application of PVC strapping is just as important as choosing the right type. Investing in quality tensioning and sealing tools can significantly improve the security and integrity of your packages.”

Conclusion

Understanding pvc strapping requirements is fundamental to efficient and secure packaging. By considering factors like tensile strength, elongation, width, and environmental conditions, you can choose the right strapping solution for your specific application. Proper application techniques further ensure the integrity of your packages, minimizing the risk of damage and loss during transit.

FAQs

- What is the difference between PVC and polyester strapping?

- How do I choose the right tensile strength for my application?

- What are the benefits of using PVC strapping?

- How do I properly apply PVC strapping?

- What are the different types of PVC strapping available?

- What are the environmental impacts of PVC strapping?

- Where can I purchase PVC strapping and application tools?

Need further assistance? Contact us at Phone Number: 0989060241, Email: [email protected] or visit us at Address: Plot 2, Hamlet 5, An Khuong, Hon Quan, Binh Phuoc, Vietnam. We have a 24/7 customer support team ready to help.