Where Are Major League Baseballs Made?

Have you ever wondered where the iconic white spheres used in Major League Baseball are crafted? The answer might surprise you. While MLB teams circle the globe, the origin of their game balls remains centralized in a small town called Coralis, located in the Dominican Republic.

The Heart of Baseball Manufacturing

Coralis, despite its unassuming size, plays a pivotal role in the world of baseball. It houses the Rawlings Sporting Goods factory, the sole manufacturer of official MLB baseballs since 1977.

A Labor of Love: Inside the Baseball Factory

The journey of an MLB baseball begins with the arrival of raw materials at the Rawlings factory. Skilled workers transform these materials into the high-quality equipment used by professional athletes.

The Core: A Journey from Coast to Coast

The baseball’s heart, a cork center encased in rubber, begins its journey in the United States. This core then travels south to the Dominican Republic, where it undergoes a meticulous transformation into the iconic baseball.

Winding and Stitching: The Human Touch

The process of creating an MLB baseball is a blend of modern machinery and meticulous handcraftsmanship. Machines wind yarn around the core, but the iconic red stitching is a testament to the skilled hands of Dominican artisans.

Dominican Artisans Hand-Stitching Baseballs

Dominican Artisans Hand-Stitching Baseballs

Why the Dominican Republic?

The choice of the Dominican Republic as the manufacturing hub for MLB baseballs is no accident. The country boasts a rich baseball heritage, producing some of the sport’s most celebrated players. This deep connection to the sport translates into a workforce with an innate understanding and passion for the game.

A Tradition of Excellence

“The Dominican people have baseball in their blood,” says [Name Surname], a veteran worker at the Rawlings factory. “We take pride in crafting the balls that our heroes use on the field.” This sentiment echoes throughout the factory, reflecting the dedication and craftsmanship poured into each baseball.

From Factory to Field: The Final Journey

Once stitched, inspected, and stamped with the commissioner’s signature, the finished baseballs are shipped to MLB teams across the United States and Canada. Each ball represents a fascinating journey, from the factory floor in Coralis to the bright lights of major league stadiums.

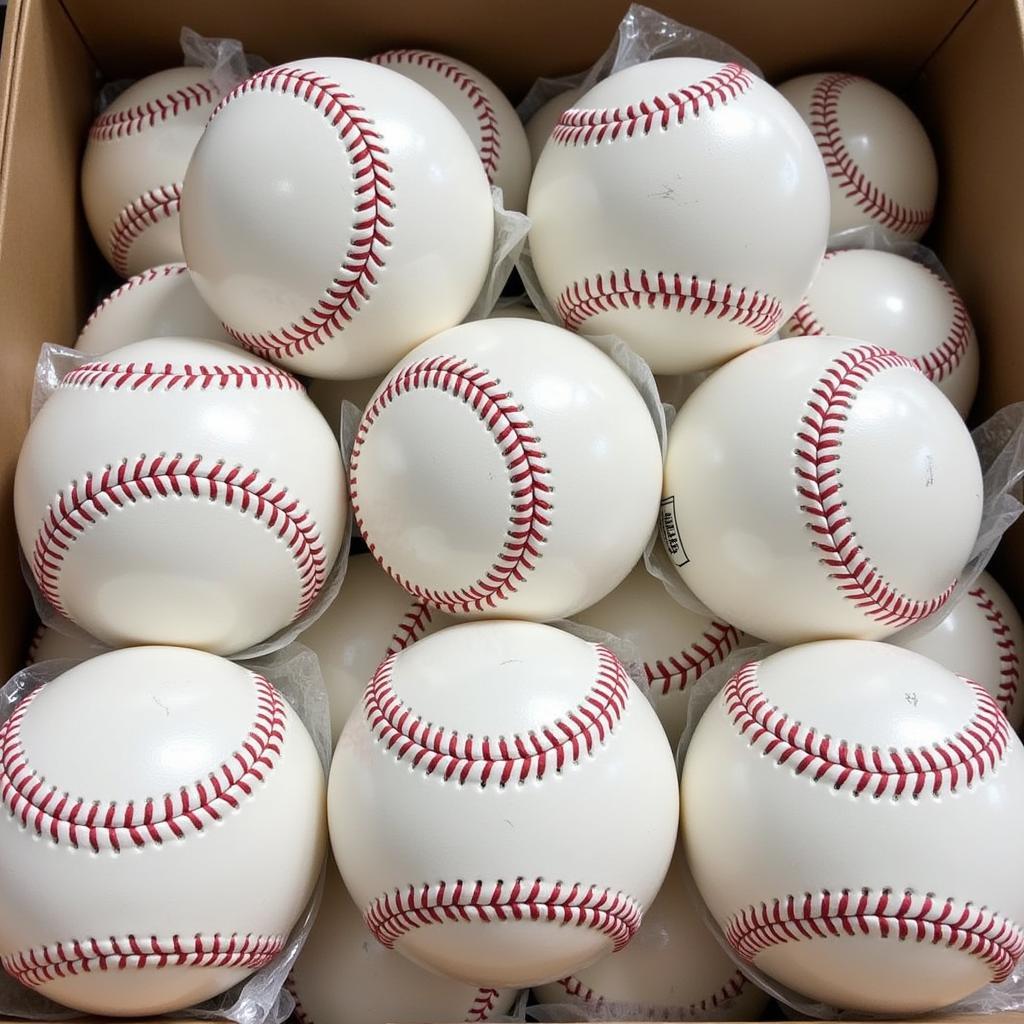

MLB Baseballs Prepared for Shipment

MLB Baseballs Prepared for Shipment

Conclusion

The next time you witness a towering home run or a diving catch in an MLB game, take a moment to appreciate the journey of the baseball itself. From the heart of the Dominican Republic to the hands of baseball legends, each ball carries a story of tradition, craftsmanship, and the enduring love for America’s pastime.

FAQs

1. How long does it take to make one MLB baseball?

It takes approximately 5-10 minutes to hand-stitch one MLB baseball, showcasing the intricate craftsmanship involved.

2. Why is the stitching on an MLB baseball red?

Red stitching is used for visibility and tradition. It helps players and fans track the ball’s spin and movement.

3. Are all MLB baseballs the same?

While all MLB baseballs meet strict specifications, slight variations can occur due to the hand-stitched nature of the process.

4. What happens to used MLB baseballs?

Used baseballs are often thrown into the stands as souvenirs or collected for authentication and historical purposes.

5. Can I visit the Rawlings factory in the Dominican Republic?

While tours aren’t always available, you can contact Rawlings for information on potential visit opportunities.

Need assistance? Contact us at Phone Number: 0989060241, Email: [email protected], or visit us at Address: Hamlet 2, Village 5, An Khương Commune, Hớn Quản District, Bình Phước Province, Vietnam. We have a dedicated customer support team available 24/7.

For more information on related topics, explore our articles on RST baseballs, baseballs MLB, and NL West teams MLB.